Best equipment, highest productivity!

We contribute to your success

Our clear goal: to increase the productivity of your company in a reliable and efficient way!

This is what our team of dedicated project managers, creative engineers and experienced technicians stand for. We develop, manufacture and assemble production equipment such as assembly jigs, access solutions, transport devices as well as assembly and equipping stations.

From the quotation up to the integration into your facilities, we retain end-to-end control of your projects. For this reason, we can promise on-time delivery and uncompromising quality at any time.

All-inclusive solutions

Since we combine several manufacturing areas - including Precision Parts and Aerospace - under one roof, our team has interdisciplinary know-how to consolidate in house. This advantage enables us to understand customer requirements from their point of view and fulfill them in an optimal way. We individually develop the most feasible solution for you.

From project planning to commissioning, our dedicated contact persons support you to make our common project a success. Most of our customers come from aerospace industry, but some are also from other sectors such as wind energy or automotive industry.

Products

In our development and design department, we create for internal and external needs:

• Feasibility studies and concept development

• Production and capacity planning

• 3D and 2D design

• CE documentation

• Stress and deformation analyses

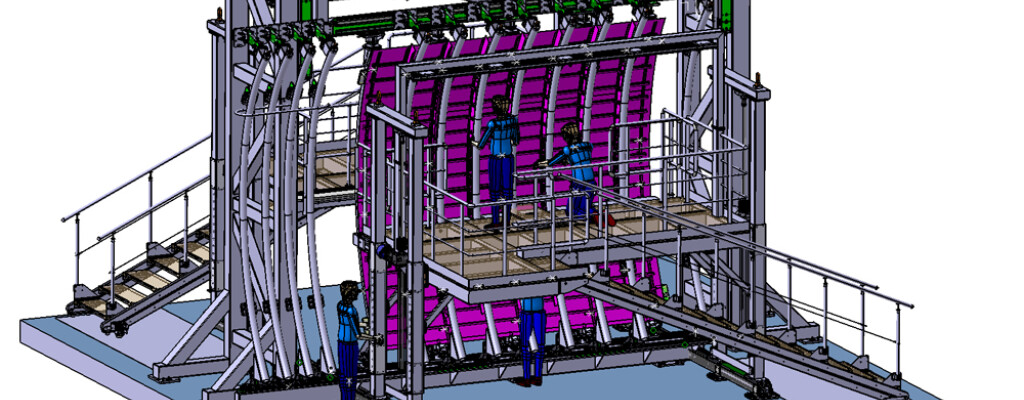

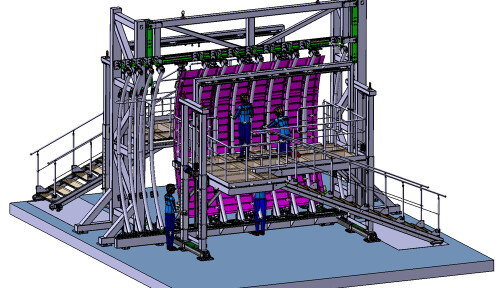

We develop and manufacture bespoke production equipment for your need:

Assembly stations

Equipping stations

Assembly jigs

Access solutions

Transport and lifting equipment

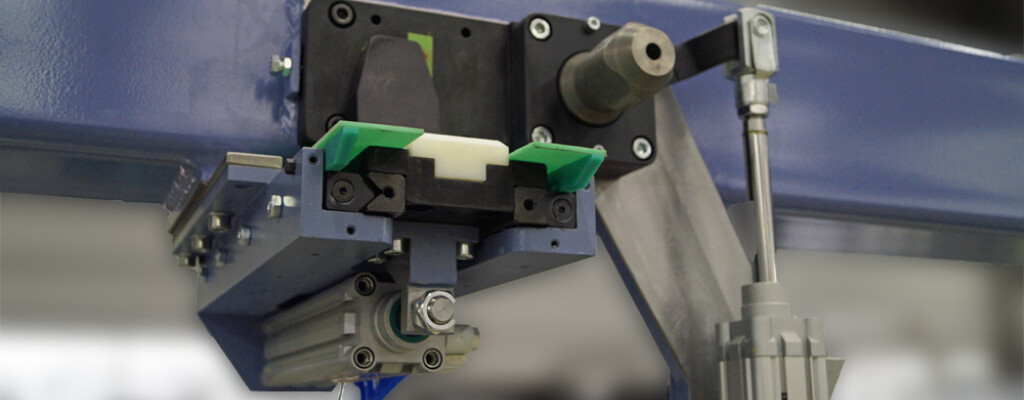

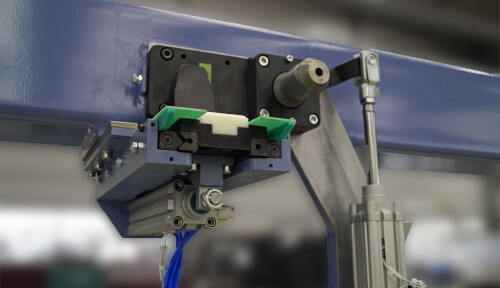

Testing equipment

Special machinery

We realize tailor-made special solutions for our customers in various industries. We also manufacture sophisticated machine components and system parts.

We automate existing systems or offer completely new systems with the appropriate level of automation:

Complete hardware and software planning of control and sensor systems

Simulations

Programming and commissioning on site

Robot programming

We provide our customers with a complete service for necessary modifications to production:

Conversion and modernization of existing production equipment

Relocation of production systems and equipment

Training of new staff

Complete handling and transport management

Our metrology services include:

Mobile 3D metrology

Positioning and installing machine components

Documenting actual conditions

Periodic inspections

Resources

We provide the following resources in design and development:

CATIA V5 as standard CAD software, release according to customer requirements

CATIA V5 and ANSYS FEM

Technical documentation

CE Coordination

Deharde has extensive internal and external resources:

Material procurement

Mechanical processing

Heat treatment

Surface protection

Quality assurance

Our welding equipment and authorisations include:

EN 1090-2 EXC3 and EN1090-3 EXC3 certification

DIN EN ISO 3834-2 certification

MIG/MAG welding

TIG welding

Micro laser welding plant

Our metrology equipment consists of:

Leica Laser Tracker

Faro measuring arm

3D coordinate measuring machines

We have an efficient coating section:

Area of 400 m²

Extraction

Trained personnel

In the assembly area we offer:

Clean, bright and consistently heated workshop

Separation of welding, painting and assembly area

3,800 square meters assembly area

25t crane capacity per bay, 4 trolley systems

Management

Arne Lübben

Head of Jigs and Tools