The driving force behind precision!

What we do

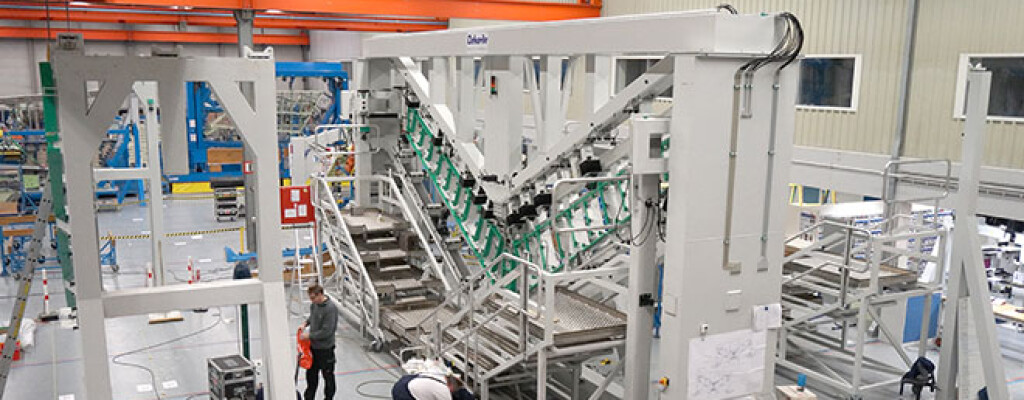

As an aerospace specialist, we focus on supplying the international aerospace industry with high-quality single parts and assemblies. Our other areas of expertise - precision parts, plant and fixture construction and wind tunnel model construction - form efficient synergies. From idea to commissioning; we offer the complete service.

Us for you

Our solutions are tailor-made. We fulfill even the most complex requirements with speed, flexibility and accuracy, frequently rescuing customers with urgent or awkward projects.

We can do this because we have short decision-making channels and are optimally positioned: with a first-class team, top equipment and maximum process efficiency.

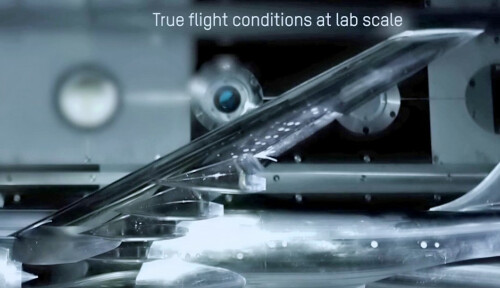

First full-model test of a remote control aileron at cryogenic conditions

A team of experts from Deharde GmbH and ETW (European Transonic Windtunnel) successfully developed a robust and patented remote control actuation for an aileron on a wind tunnel model. We provided the technology. This technology is a step change in productivity for testing at real flight conditions which are achieved at cryogenic temperatures and high pressure in the wind tunnel.

The German Federal Ministry for Economic Affairs and Energy supported this research study in the context of a LuFo-project.