Space for XL service!

From single parts to assemblies

We offer complete service for the civil and military aerospace industry worldwide: with more than 150 qualified processes, we can serve the entire production chain, including assembly, development of subassemblies and test equipment.

As a Tier 1, we supply Airbus and other well-known aerospace manufacturers in series production with ready-to-install assemblies.

Taking off together

Your process requirements are our benchmark: we establish not-yet-utilised processes in a quick and flexible manner in order to meet your component manufacturing and assembly requirements. You benefit from the incorporation of the latest technical findings and innovative ideas. We continuously improve ourselves in order to be the competent partner for major aviation manufacturers (OEMs).

Should a customer at any time need quick support, we step in with efficient recovery measures.

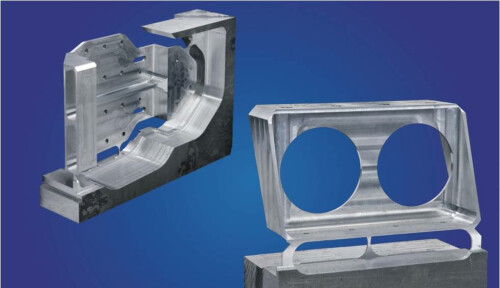

Products

We deliver prefabricated components for further processing by the customer:

Material procurement

Manufacturing blanks

Preparing boreholes

Pre-milling

Collection, temporary storage, punctual delivery

Maximum processing size 7,200 x 2,800 mm

Complete production of ready-to-install individual parts as well as ready-to-install aerostructures according to the quality assurance requirement QSF-A and QSF-B of the Federal Association of the German Aviation Industry.

NC programming

Material procurement

Materials: aluminum, titanium, steel, plastics

Component lengths up to 5000 mm

Complete production according to technical drawings

Manufacturing

Structural assembly

Surface protection

Quality assurance

Installation of systems

Testing

On-time delivery directly to the customer's assembly line

During the test phase of new aircraft, we support our customers with the design and manufacture of test equipment:

Any kind of test installation to customer requirements

Custom solutions for the positioning of measuring instruments

Ballast-tank systems

Manufacture of prototypes to determine technological properties

Complete end-to-end service: from design to installation

Resources

Deharde Aerospace has extensive internal and external resources:

Material procurement

Mechanical processing

Heat treatment

Surface protection

Quality assurance

Further information about our production capabilities is available in our "Machining” section"

For the complete assembly of ready-to-install modules, we have available:

Secured assembly areas

Qualified staff for all required assembly processes

Surface protection

In order to deliver modules and components to our customers on time, our logistics is controlled directly through our ERP system:

Consumption-based stocking of connecting elements and standard parts

Make-to-stock production of series components

Storage of long lead-time parts on demand

Picking stock on demand

Organisation of collection and on-time delivery directly to the customer’s assembly line

Our in-house plant engineering designs and builds production equipment in close coordination with our aerospace sector, thus producing high synergic effects:

Conceptualisation

Production planning

Storage of long lead-time parts on demand

Development, manufacture and commissioning of production equipment

Periodic inspections to ensure quality

Further information about our services is available in our "Plant section".

Management